Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

You often find lithium aluminum hydride at the heart of organic synthesis because it acts as a powerful reducing agent. Its unmatched reactivity lets you convert carboxylic acid derivatives to primary alcohols, a transformation that sodium borohydride cannot achieve. When you use lithium aluminum hydride, the hydride attacks the carbonyl group after deprotonation, and the aluminum coordinates with the oxygen, making the reduction process much more efficient. This selectivity and strength make it a staple in modern chemistry labs.

You encounter lithium aluminum hydride as a strong reducing agent in many organic synthesis protocols. LiAlH4 stands out because it delivers hydride ions with high nucleophilicity. You use it to break down a wide range of functional groups, making it essential for modern synthesis. When you need to transform complex molecules, LiAlH4 gives you the power to reduce esters, nitriles, carboxylic acids, and nitro groups. This versatility means you can access alcohols and amines from many starting materials.

Tip: Always remember that LiAlH4 reacts violently with water. You must handle it in dry solvents like ether to keep your synthesis safe and controlled.

Here is a quick overview of the most common transformations you perform using lithium aluminum hydride in organic synthesis:

Type of Transformation | Description |

|---|---|

Reduction of esters to alcohols | Converts esters into their corresponding alcohols. |

Reduction of nitriles to amines | Transforms nitriles into amines. |

Reduction of carboxylic acids to alcohols | Reduces carboxylic acids to alcohols. |

Reduction of nitro groups to amines | Changes nitro groups into amines. |

You see that LiAlH4 covers a broad spectrum of reductions, which makes it a strong reducing agent for many synthesis pathways.

LiAlH4 shows high reactivity in organic synthesis. You notice that it reduces almost all carbonyl-containing functional groups. This includes aldehydes, ketones, esters, and carboxylic acids. When you use LiAlH4, you do not need to worry about selectivity between these groups because it reduces them all. This property sets it apart from other strong reducing agents.

You might compare LiAlH4 with sodium borohydride. Sodium borohydride is less reactive. You use it when you want to reduce aldehydes and ketones but leave esters untouched. LiAlH4 does not offer this selectivity. It reduces esters, carboxylic acids, and even nitro groups. You choose LiAlH4 when you need complete reduction in your synthesis.

LiAlH4’s high reactivity comes from the polar covalent bond between aluminum and hydrogen. This bond makes the hydride ion very reactive. You cannot use protic solvents like water because LiAlH4 reacts violently. You must use dry, aprotic solvents to keep your synthesis safe.

Note: If you need selective reduction, you can use modified reagents like lithium tri-tert-butoxyaluminum hydride. This reagent reduces acid chlorides to aldehydes without further reduction to alcohols. The bulky tert-butoxy groups slow down the reaction, giving you more control in your synthesis.

You rely on lithium aluminum hydride for its unmatched strength and broad reactivity. When you plan your organic synthesis, you choose LiAlH4 for transformations that require a strong reducing agent and complete reduction of functional groups.

When you choose a reducing agent for your synthesis, you often compare sodium borohydride and lialh4. Both agents deliver hydride ions, but their reactivity and selectivity differ. You find that lialh4 acts as a much stronger reducing agent. It can reduce a wider range of functional groups, including esters and amides, while sodium borohydride works best with aldehydes and ketones.

You can see the key mechanistic differences in the table below:

Reducing Agent | Reactivity Level | Mechanism Description |

|---|---|---|

Lithium Aluminum Hydride | Strong | Nucleophilic attack on carbonyl, forms tetrahedral intermediate, expels leaving group, reduces esters and amides to alcohols and amines. |

Sodium Borohydride | Weaker | Less effective for amides, can reduce esters slowly, different leaving groups and intermediates involved. |

When you use lialh4, you observe that it attacks the carbonyl group directly. This forms a tetrahedral intermediate, which then collapses and expels the leaving group. As a result, lialh4 reduces esters to alcohols and amides to amines efficiently. Sodium borohydride, on the other hand, struggles with esters and amides. You may see slow or incomplete reactions if you try to use sodium borohydride for these transformations.

You also notice that lialh4 requires careful handling. It reacts violently with water, so you must use dry solvents. Sodium borohydride is safer and easier to handle, but you sacrifice reactivity for convenience.

You have more options than just lialh4 and sodium borohydride. Other reducing agents, such as DIBAL-H and borane, offer unique selectivity and efficiency. When you want to stop at the aldehyde stage during ester reduction, DIBAL-H gives you that control. Lialh4, in contrast, reduces esters all the way to primary alcohols. This difference can change your entire synthetic plan.

DIBAL-H selectively reduces esters to aldehydes without further reduction to alcohols, while lialh4 reduces esters to primary alcohols.

Yields for DIBAL-H reductions often exceed 90%, showing high efficiency.

If you use lialh4 and want an aldehyde, you must oxidize the alcohol product, which adds another step.

Borane also offers selectivity for certain reductions, but lialh4 remains the most versatile when you need complete reduction. You choose lialh4 when you want to convert carboxylic acids, esters, and amides to their fully reduced forms. If you need more control or higher selectivity, you might reach for DIBAL-H or borane instead.

You should always match your reducing agent to your synthetic goal. Lialh4 gives you power and broad reactivity, but sometimes you need the precision of DIBAL-H or the safety of sodium borohydride. By understanding these differences, you can design more efficient and successful syntheses.

You often use lithium aluminum hydride when you need to achieve the reduction of carboxylic acid derivatives. This reagent stands out because it can reduce carboxylic acids to primary alcohols with high efficiency. You will notice that sodium borohydride does not work for this transformation, so you must choose lialh4 for success. When you add lialh4 to a carboxylic acid, the reaction proceeds smoothly, and you obtain a primary alcohol as the main product.

Lithium aluminum hydride reduces all classes of carboxylic acid derivatives to primary alcohols.

You find that lialh4 outperforms other reducing agents, especially sodium borohydride, which cannot reduce carboxylic acids.

Catalytic reduction methods do not match the efficiency of lialh4 for this transformation.

Tip: Always use dry solvents like diethyl ether or tetrahydrofuran when you perform the reduction of carboxylic acid derivatives. Water will react violently with lialh4.

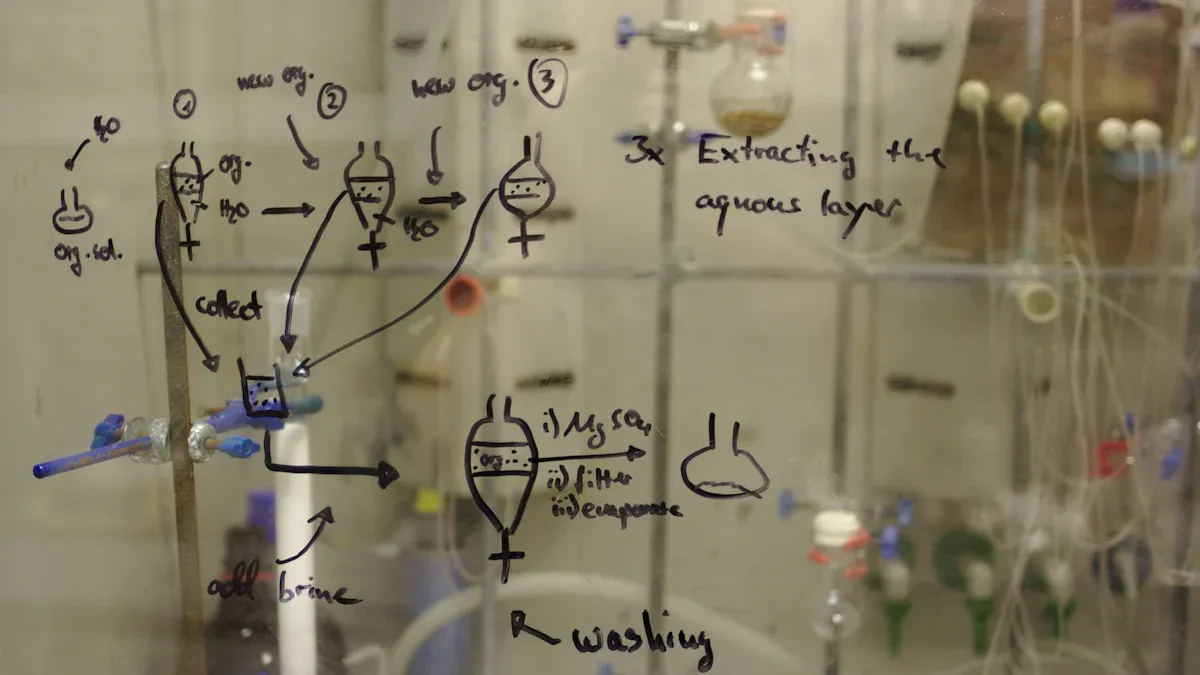

You can also use lialh4 for the reduction of esters. This reaction allows you to convert esters into primary alcohols, which is a valuable transformation in organic synthesis. The reduction of esters with lialh4 usually takes place in diethyl ether or tetrahydrofuran. After the reaction, you need to add aqueous acid to complete the process and isolate your alcohol product.

The reduction of esters involves two hydride additions to the carbonyl group.

An aldehyde intermediate forms during the reaction, but it reacts quickly with another equivalent of lialh4.

You typically use diethyl ether or tetrahydrofuran as the solvent.

A final work-up with aqueous acid (H3O+) is necessary to obtain the alcohol.

You will see that the reduction of esters with lialh4 gives you high yields and clean products. This method is much more effective than the reduction of aldehydes and ketones with sodium borohydride, which cannot reduce esters efficiently.

When you need to perform the reduction of amides, lialh4 is your reagent of choice. The reduction of carboxylic acid derivatives like amides to amines is a key step in many syntheses. The mechanism involves several steps:

Step | Description |

|---|---|

1 | Nucleophilic attack by the hydride ion at the carbonyl carbon to form a tetrahedral intermediate. |

2 | The carbonyl oxygen reacts with aluminum hydride to form an oxygen–aluminum bond. |

3 | Rearrangement of electron pairs occurs, expelling the aluminate anion as a leaving group to form an iminium ion intermediate. |

4 | A second nucleophilic attack on the iminium ion by the hydride yields the final amine product. |

You need two equivalents of lialh4 for the reduction of amides. This process works for primary, secondary, and tertiary amides, giving you the corresponding amines. The reduction of amides by lialh4 involves nucleophilic acyl substitution, which is different from the reduction of aldehydes and ketones.

Note: The reduction of acid halides, esters, and amides with lialh4 gives you a wide range of alcohols and amines, making this reagent essential for the reduction of carboxylic acid derivatives.

You can see that lialh4 enables the reduction of acid halides, esters, and amides, while sodium borohydride is limited to the reduction of aldehydes and ketones. This broad reactivity makes lithium aluminum hydride a powerful tool for the reduction of carboxylic acid derivatives in modern organic synthesis.

You often need to convert nitriles into primary amines during organic synthesis. Lithium aluminum hydride gives you a reliable method for this transformation. When you add LiAlH4 to a nitrile, the hydride ion attacks the carbon atom in the nitrile group. This step forms an imine anion, which then reacts further to produce a primary amine. You see that the reduction of nitriles is a powerful tool for building amine groups in molecules.

Note: The reaction between nitriles and LiAlH4 can be vigorous. You should always control the temperature and use dry solvents to keep the process safe.

You may notice that the reduction of nitriles sometimes requires elevated temperatures. This helps the reaction proceed to completion. In some cases, chemists have explored catalytic methods using LiAlH4. These approaches can reduce hazardous work-ups and limit unwanted side products. You gain more control over the reaction and improve safety in your lab.

Here is a simple overview of the process:

You add LiAlH4 to the nitrile in a dry solvent.

The hydride attacks the nitrile carbon, forming an imine salt.

You apply heat if needed to drive the reaction forward.

After the reaction, you perform an aqueous work-up to isolate the primary amine.

Step | Description |

|---|---|

Hydride Addition | Hydride attacks nitrile carbon, forms imine anion |

Intermediate | Imine salt forms, may require heating |

Work-up | Aqueous acid releases primary amine |

You should know that side reactions can occur. Sometimes, the reaction produces alcohols or aldehydes instead of amines. This complexity means you must monitor your reaction carefully. You may need to adjust conditions to get the best yield of your desired product.

Tip: If you want to avoid side products, you can try using catalytic amounts of LiAlH4. This method can help you achieve cleaner reactions and easier purification.

The reduction of nitriles with LiAlH4 lets you access primary amines from simple starting materials. You use this reaction to build molecules for pharmaceuticals, agrochemicals, and polymers. When you plan your synthesis, consider the scope and limitations of LiAlH4. You can achieve efficient reductions, but you must pay attention to reaction conditions and possible side reactions.

You use lialh4 in organic synthesis because it delivers hydride ions with remarkable efficiency. When you add lialh4 to a reaction mixture, the hydride ions attack the carbon atom in the carbonyl group. This step breaks the double bond and forms a new intermediate. You see this process in many reduction reactions, especially when you want to convert esters, amides, or carboxylic acids into alcohols or amines.

The mechanism starts with lialh4 donating a hydride to the carbonyl carbon. The oxygen atom then bonds to the aluminum, which stabilizes the intermediate. You notice that this step is fast and often leads to complete conversion of your starting material. In most reduction reactions, you need to add an acid during the work-up to release the final product from the aluminum complex.

Here is a simple outline of the hydride transfer process:

You add lialh4 to your substrate in a dry solvent.

The hydride attacks the carbonyl carbon, forming a tetrahedral intermediate.

The oxygen bonds to aluminum, stabilizing the intermediate.

You add acid to break the aluminum-oxygen bond and release the alcohol or amine.

Tip: You should always use lialh4 in anhydrous conditions. Water reacts violently with lialh4 and can destroy your substrate.

You control the outcome of lialh4 reduction reactions by adjusting the reaction conditions. The choice of solvent, temperature, and concentration all play important roles. You often use dry ether or tetrahydrofuran because these solvents dissolve both lialh4 and your substrate. These solvents also help you separate the products after the reaction.

You need to pay close attention to temperature. If you heat the reaction too much, you risk decomposing your product or forming unwanted impurities. You should keep the temperature low to maximize your yield. Sometimes, you use ice baths or controlled heating to manage the reaction rate.

You also adjust the concentration of lialh4 and your substrate. Lower concentrations give you better control and help you manage the temperature. However, you may see higher production costs if you use more solvent or dilute your reagents.

Lower concentration of lialh4 or substrate increases production costs but allows for better control of the reaction and temperature management.

Optimal reaction temperature is crucial for maximizing product yield; excessive heat can lead to product decomposition and impurities.

The choice of solvent can influence the reaction mechanism and is essential for dissolving substrates and ensuring effective separation of products.

You see that every detail matters when you use lialh4. You must choose the right solvent, control the temperature, and adjust concentrations to get the best results. These factors help you achieve clean reduction reactions and high yields.

Note: You should always monitor your reaction closely. Small changes in conditions can have a big impact on the outcome when you use lialh4.

You can use lialh4 to open epoxide rings and create valuable alcohols. This reaction works well for many types of epoxides. When you add lialh4, the hydride attacks the less hindered carbon in the epoxide. This approach gives you control over the product you make. You often see this reaction in the synthesis of complex molecules.

Lialh4 reduces epoxides by attacking the less hindered end.

You usually get secondary or tertiary alcohols as products.

Epoxycyclohexanes convert to axial alcohols with high selectivity.

You can use this method to prepare alcohols that are hard to make by other routes. The reaction works under mild conditions, so you protect sensitive groups in your molecule. You should always add lialh4 slowly to avoid side reactions. After the reaction, you add water or acid to finish the process and isolate your alcohol.

Tip: If you want to control the stereochemistry of your product, choose the right epoxide and reaction conditions. Lialh4 gives you a powerful tool for making specific alcohols.

Lialh4 also helps you reduce alkyl halides to alkanes. You use this reaction when you want to remove a halogen atom from your molecule. The hydride from lialh4 replaces the halide, and you get a simple hydrocarbon. This method works best for primary and secondary alkyl halides. Tertiary halides react more slowly.

You often use this reaction to remove protecting groups or to simplify a molecule. The process is straightforward. You mix your alkyl halide with lialh4 in a dry solvent. The reaction produces an alkane and a lithium halide salt. You finish the reaction by adding water to destroy any leftover lialh4.

Note: Lialh4 does not work well with aryl halides or vinyl halides. You should use other methods for those compounds.

You can use lialh4 to reduce nitro compounds to amines. This reaction is important in the synthesis of pharmaceuticals and dyes. When you treat a nitro group with lialh4, the hydride ions attack the nitrogen atom. The reaction goes through several steps and gives you a primary amine at the end.

You often choose lialh4 for this reduction because it works under mild conditions. You avoid harsh acids or metals. The reaction is clean and gives you high yields. You should monitor the reaction carefully, as over-reduction can sometimes occur.

Lialh4 reduces nitro groups to primary amines.

The reaction avoids the need for metal catalysts.

You get high yields and fewer side products.

Tip: Always use dry solvents and add lialh4 slowly. This practice keeps your reaction safe and efficient.

You see that lialh4 is not just for carbonyl reductions. You can use it to open epoxides, remove halides, and make amines from nitro groups. This versatility makes lialh4 a key reagent in your organic synthesis toolkit.

You must treat lialh4 with great care in the laboratory. This reagent reacts violently with water and moist air, so you need to keep it dry at all times. You store lialh4 in tightly sealed containers, placing them in a cool, dry area away from anything that can burn. You should never leave lialh4 exposed to the atmosphere. You handle lialh4 only in areas free of ignition sources and always under an inert atmosphere, such as nitrogen or argon. You protect yourself by wearing safety glasses, impermeable gloves, and a fire-retardant laboratory coat. You keep a dry powder fire extinguisher or a pail of sand nearby in case of emergencies. You work with large amounts of lialh4 in a fume hood to prevent exposure. If lialh4 touches your skin, you wash immediately with soap and water. If it gets in your eyes, you rinse with water for 15 minutes and seek medical help.

Store lialh4 in tightly sealed containers in a cool, dry place.

Avoid water and moist air to prevent violent reactions.

Handle lialh4 under an inert atmosphere, such as nitrogen or argon.

Wear safety glasses, gloves, and a fire-retardant lab coat.

Keep a dry powder fire extinguisher or sand nearby.

Use a fume hood for large quantities.

Wash skin immediately if contact occurs; rinse eyes for 15 minutes and get medical attention.

Tip: You should always check your storage area for leaks or moisture before you bring out lialh4.

You face several risks when you work with lialh4. You must understand the most common safety incidents and learn how to prevent them. You should never open a container of lialh4 near flammable materials. You write and review a Standard Operating Procedure before you start any experiment with lialh4. You use only Met-L-X® dry powder fire extinguishers for metal hydride fires, not CO2 extinguishers. You keep your workspace clear of unrelated experiments and flammable items. You handle lialh4 under an inert atmosphere and store it away from heat, oxidizers, and moisture. You wear flame-resistant lab coats, protective eyewear, and gloves every time you use lialh4. You make sure you receive regular training on emergency response and fire extinguisher use.

Contributing Factors | Precautions |

|---|---|

Open container of lialh4 near flammable materials | Review and write a Standard Operating Procedure before working with lialh4. |

Incorrect fire extinguisher used (CO2) | Use Met-L-X® dry powder fire extinguishers for metal hydride fires. |

Adjacent experiments with combustible materials | Keep work area clear of unrelated experiments and flammable items. |

Improper handling and storage | Handle lialh4 under inert atmosphere and store away from heat, oxidizers, and moisture. |

Lack of appropriate PPE | Wear flame-resistant lab coats, protective eyewear, and gloves. |

Inadequate emergency response training | Ensure periodic refresher training on fire extinguisher use. |

Note: You should always plan your experiment and review safety procedures before you use lialh4.

You need to think about the environmental impact when you use lialh4. This reagent can create hazardous waste if you do not dispose of it properly. You must never pour leftover lialh4 down the drain. You neutralize unused lialh4 with a controlled addition of isopropanol or ethanol under an inert atmosphere. You collect all waste and send it to a chemical disposal facility. You reduce environmental risks by using only the amount of lialh4 you need for your experiment. You can also look for alternative reducing agents that have less impact, such as sodium borohydride, when your reaction does not require the full strength of lialh4.

Neutralize unused lialh4 with alcohol under inert conditions.

Collect and dispose of all lialh4 waste through proper channels.

Use only the necessary amount of lialh4 to minimize waste.

Consider alternative reagents for less hazardous reactions.

Tip: You help protect the environment by following all disposal guidelines and choosing safer alternatives when possible.

You have explored the essential role of lialh4 in organic synthesis. This reagent gives you powerful options for reducing a wide variety of functional groups. When you need to transform carboxylic acids, esters, amides, or nitriles, lialh4 stands out as your go-to choice. You see that lithium aluminum hydride offers unmatched strength and versatility compared to other reducing agents.

Take a look at the main advantages of lialh4, as highlighted by recent review articles:

Advantage | Description |

|---|---|

Strong Reducing Agent | Lialh4 is stronger than NaBH4, making it more effective for reductions. |

Versatility | You can reduce carboxylic acids, esters, nitriles, and more with lialh4. |

All-Purpose Use | Lialh4 works well when you need a functional group reduced quickly and fully. |

You notice that lialh4 does not just work for one type of reaction. You can use it to reduce carboxylic acids to alcohols, esters to alcohols, amides to amines, and nitriles to amines. This broad reactivity makes lialh4 a staple in your laboratory. You do not need to switch reagents for different reductions. Lialh4 covers most of your needs.

Tip: When you plan your synthesis, always consider the strength and scope of lialh4. You save time and increase your yield by choosing the right reagent from the start.

You also learn that lialh4 requires careful handling. You must use dry solvents and protect yourself with proper safety gear. You store lialh4 away from moisture and heat. You follow strict disposal guidelines to protect the environment. These steps help you avoid accidents and keep your lab safe.

Here are some key points to remember about lialh4:

You achieve complete reduction of many functional groups.

You work with a reagent that is stronger than sodium borohydride.

You handle lialh4 with care to prevent dangerous reactions.

You choose lialh4 when you need fast and effective reductions.

You now understand why lithium aluminum hydride remains a favorite in modern organic synthesis. Lialh4 gives you the flexibility to tackle complex transformations. You can rely on its power and versatility for a wide range of reactions. When you need results, lialh4 delivers.

You rely on lithium aluminum hydride for strong reductions in organic synthesis. This reagent helps you convert carboxylic acids and esters to primary alcohols, which other agents cannot achieve. You choose lithium aluminum hydride when you need powerful results, especially in pharmaceutical work. Consider these points before you start:

You must handle it in dry, oxygen-free conditions.

Scaling up reactions can be difficult due to heat and safety risks.

Disposal of aluminum salts requires special care.

Think about both the advantages and the practical challenges when you plan your next synthesis.

You use lithium aluminum hydride to reduce carboxylic acids, esters, amides, and nitriles. This reagent helps you convert these groups into alcohols or amines, making it essential for many organic transformations.

You cannot use lithium aluminum hydride with water. It reacts violently and can cause fires or explosions. Always choose dry solvents like ether or tetrahydrofuran for safe handling.

You neutralize leftover lithium aluminum hydride by slowly adding isopropanol or ethanol under an inert atmosphere. Collect all waste and send it to a chemical disposal facility. Never pour it down the drain.

You cannot reduce aryl halides, alkenes, or alkynes with lithium aluminum hydride. It works best with carbonyl-containing groups and some nitrogen-containing compounds.

You need an inert atmosphere, such as nitrogen or argon, to prevent moisture and oxygen from reacting with lithium aluminum hydride. This practice keeps your experiment safe and avoids dangerous side reactions.

You should wear safety glasses, flame-resistant lab coats, and impermeable gloves. These items protect you from chemical burns and fires when working with lithium aluminum hydride.

You store lithium aluminum hydride in tightly sealed containers in a cool, dry place. Keep it away from moisture, heat, and flammable materials to prevent accidents.

Tip: Always check your storage area for leaks or moisture before you use lithium aluminum hydride.