Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

You often need a strong reducing agent for organic synthesis, especially when you want to transform tough functional groups. Lithium borohydride gives you a powerful option for reducing esters, amides, and carboxylic acids. You can also use it to open epoxides and carry out chemical processes that other agents cannot handle. Its selectivity sets it apart from sodium borohydride, letting you choose the best method for your reducing needs.

You use lithium borohydride as a powerful source of hydride ion in organic synthesis. The mechanism for the reduction starts with a nucleophilic attack by the hydride anion on the carbonyl carbon. This nucleophilic addition to carbonyls creates an alkoxide intermediate. You then protonate the alkoxide to form the corresponding alcohol. The steps in this mechanism for the reduction look like this:

The hydride ion from lithium borohydride attacks the carbonyl carbon in the substrate.

You see the formation of an alkoxide intermediate after this nucleophilic addition to carbonyls.

You add a proton to the alkoxide, which gives you the alcohol as the final product.

This mechanism works well for many reactions, especially when you need to reduce esters, amides, and carboxylic acids. Lithium borohydride acts as a strong source of hydride ion, making it more effective than nabh4 in these reactions.

Lithium borohydride donates hydride ions to electrophilic carbon atoms in carbonyl groups. You rely on this electron donation to start the reduction process. The nucleophilic addition to carbonyls leads to the formation of alkoxide intermediates. You convert these intermediates into alcohols by protonation. The mechanism for the reduction involves:

Lithium borohydride provides a hydride ion as the source of hydride ion.

The hydride ion attacks the carbonyl carbon, causing nucleophilic addition to carbonyls.

You get an alkoxide intermediate, which you then protonate to yield the alcohol.

You use lithium borohydride in reactions where nabh4 cannot reduce the substrate efficiently. The electron donation step is crucial for the reduction of tough functional groups.

Lithium borohydride shows high selectivity in reduction reactions. You can reduce esters, amides, and carboxylic acids with this reagent. You also use it to open epoxides, which makes it versatile in organic synthesis. The mechanism for the reduction allows you to target functional groups that nabh4 cannot reduce easily. You see lithium borohydride acting as a strong source of hydride ion in these reactions.

You often choose lithium borohydride when you need to reduce carbonyls that resist nabh4. The nucleophilic addition to carbonyls is more efficient with lithium borohydride, especially for esters and amides. You also use it for reactions involving carboxylic acids and epoxides, where nabh4 is less effective.

You may wonder how lithium borohydride compares to nabh4 in reduction reactions. The table below shows the differences in reactivity and suitable reductions:

Compound | Reactivity Level | Suitable Reductions |

|---|---|---|

Lithium Borohydride | Higher | Esters, Carboxylic Acids, Amides |

Sodium Borohydride | Lower | Aldehydes, Ketones, Acid Chlorides |

You see that lithium borohydride offers higher reactivity. You use it for reduction of esters, amides, and carboxylic acids. Sodium borohydride will reduce aldehydes, ketones, and acid chlorides, but it cannot handle tougher substrates. You choose lithium borohydride when you need a stronger reducing agent for challenging reactions.

Tip: You should select lithium borohydride when you want to perform reduction reactions on functional groups that resist nabh4. This choice gives you better yields and more efficient mechanisms.

You often encounter esters in organic synthesis, especially when you want to create alcohols. Lithium borohydride gives you a reliable way to perform this reduction. The reaction starts with a nucleophilic addition of the hydride ion to the carbonyl carbon in the ester. This mechanism forms an alkoxide intermediate. You then add a proton to convert the intermediate into an alcohol. The reduction of esters with lithium borohydride works well because the lithium ion coordinates with the carbonyl oxygen, making the carbonyl more reactive. This coordination increases the rate of nucleophilic addition and improves the overall reaction yield.

You can compare the reduction of esters using lithium borohydride to nabh4. Nabh4 often fails to reduce esters efficiently, but lithium borohydride handles these reactions with ease. The mechanism involves a direct hydride transfer, which makes the process straightforward. You can see the transformation summarized in the table below:

Organic Compound Type | Reduced To |

|---|---|

Esters | Alcohols |

Note: You should choose lithium borohydride for ester reductions when nabh4 does not give you the desired results.

You use lithium borohydride to reduce amides to amines. This reaction is important in the synthesis of pharmaceuticals and fine chemicals. The mechanism involves a nucleophilic addition of the hydride ion to the carbonyl carbon of the amide. The lithium ion acts as a Lewis acid, coordinating with the carbonyl oxygen. This coordination lowers the electron density on the oxygen and makes the carbonyl more susceptible to nucleophilic attack. The reaction proceeds through an intermediate, which you then protonate to yield the amine.

You may notice that nabh4 does not reduce amides effectively. Lithium borohydride provides a stronger reducing environment, which allows you to complete these reactions. The mechanism is less complex than the one used by lithium aluminum hydride, which involves multiple steps and intermediates. You benefit from a simpler and safer process when you use lithium borohydride.

The hydride addition to the carbonyl is facilitated by the lithium ion.

The lithium ion acts as a Lewis acid, enhancing the reactivity of the carbonyl group.

You achieve efficient reduction of amides to amines.

Carboxylic acids are among the most challenging functional groups to reduce. You can use lithium borohydride to convert carboxylic acids into alcohols. The reaction begins with a nucleophilic addition of the hydride ion to the carbonyl carbon. The lithium ion again coordinates with the carbonyl oxygen, increasing the reactivity of the carbonyl group. This mechanism allows you to achieve reductions that nabh4 cannot perform.

You often choose lithium borohydride for these reactions because it offers a direct and efficient pathway. The mechanism involves hydride addition, intermediate formation, and protonation to yield the alcohol. You can summarize the transformation as follows:

Carboxylic acids undergo reduction to alcohols.

The reaction uses a nucleophilic addition mechanism.

Lithium borohydride outperforms nabh4 in these reductions.

Tip: When you need to reduce tough carboxylic acids, lithium borohydride gives you a practical and effective solution.

You often need to convert nitriles into primary amines in organic synthesis. Lithium borohydride gives you a strong option for this reduction. The mechanism starts with a nucleophilic addition of the hydride ion to the carbon atom in the nitrile group. You see the formation of an imine intermediate. You then add more hydride ions, which leads to the reduction of the imine to an amine. The reaction works well because lithium borohydride provides a powerful source of hydride ions.

You use this reduction when you want to avoid harsher conditions. The mechanism is straightforward. You add lithium borohydride to the nitrile. The nucleophilic attack breaks the triple bond. You get an imine, which then undergoes further reduction to form the amine. You can summarize the steps:

Nucleophilic addition of hydride to the nitrile carbon.

Formation of imine intermediate.

Further reduction to primary amine.

Tip: You should choose lithium borohydride for the reduction of nitriles when you need a mild and efficient reaction.

You often encounter epoxides in organic synthesis. These compounds have a strained three-membered ring. Lithium borohydride helps you open this ring through a reduction reaction. The mechanism involves nucleophilic addition of the hydride ion to one of the carbon atoms in the epoxide. You see the ring open, and you get an alcohol as the product.

You use this reaction when you want to create alcohols from epoxides. The mechanism is simple. You add lithium borohydride to the epoxide. The nucleophilic attack breaks the ring. You get an alkoxide intermediate, which you then protonate to form the alcohol. The reaction works well because lithium borohydride provides a strong hydride source.

Nucleophilic addition opens the epoxide ring.

You form an alkoxide intermediate.

Protonation gives you the alcohol.

You often choose lithium borohydride for epoxide opening when nabh4 does not give you good yields. The mechanism is efficient, and the reaction is easy to control.

You frequently perform the reduction of aldehydes in organic synthesis. Lithium borohydride gives you a reliable method for this reaction. The mechanism starts with nucleophilic addition of the hydride ion to the carbonyl carbon in the aldehyde. You form an alkoxide intermediate. You then protonate the intermediate to get a primary alcohol.

You may wonder how lithium borohydride compares to nabh4 for the reduction of aldehydes. Both agents give you the same products. You get primary alcohols from aldehydes and secondary alcohols from the reduction of ketones. Sodium borohydride (nabh4) is gentler and safer. You can use nabh4 in alcohol or water solutions. Lithium borohydride requires you to exclude water and alcohol from the reaction. You need to choose the right agent based on your reaction conditions.

Here is a comparison:

Reducing Agent | Reactivity Level | Suitable Solvents | Products from Aldehydes |

|---|---|---|---|

Lithium borohydride | High | Dry, aprotic solvents | Primary alcohols |

nabh4 | Moderate | Alcohol, water | Primary alcohols |

You use lithium borohydride when you need a stronger reduction. You use nabh4 when you want safer and more versatile reactions. The mechanism for both agents involves nucleophilic addition to the carbonyl carbon, formation of an alkoxide, and protonation to yield the alcohol.

Note: You should select lithium borohydride for the reduction of aldehydes when you need higher reactivity. You should use nabh4 for safer and more flexible reaction conditions.

You need to choose the right solvent for lithium borohydride reduction. Solvents play a key role in controlling the reaction and ensuring safety. You often use 5- or 6-membered cyclic ethers, such as tetrahydrofuran (THF) or 2-methyltetrahydrofuran. Polyfunctional ethers like 1,2-dimethoxyethane also work well. These solvents stabilize lithium borohydride and support efficient reduction reactions.

Thermal gravimetric analysis shows that LiC4-THF keeps 75% of its mass above 300 °C. You get high thermal stability in your reactions.

Raman spectroscopy confirms that no free THF exists in the ionic liquid. You see a stable Li+-THF solvation complex, which helps the reduction proceed smoothly.

Lithium metal soaked in LiC4-THF for a month shows no corrosion. You can trust this solvent for safe and reliable reactions.

Tip: You should avoid water and alcohol as solvents. These can react with lithium borohydride and stop the reduction.

You must handle lithium borohydride with care. You should keep it dry and away from moisture. You need to use gloves and eye protection during preparation. You should weigh the reagent quickly and transfer it to the reaction vessel without delay. You must seal the container tightly to prevent exposure to air. You should store lithium borohydride in a cool, dry place.

Preparation Method | Details |

|---|---|

Preferred Solvents | 5- or 6-membered cyclic ethers (THF, 2-methyltetrahydrofuran), polyfunctional ethers (1,2-dimethoxyethane) |

Reaction Temperature | 10° C to boiling point of solvent; best range is 30-70° C |

Reaction Pressure | Normal or slight excess (up to 100 mbar) |

Operation Type | Semi-batch: introduce LiH first, then meter in BF3 |

Stirring Time | 1 to 3 hours after BF3 addition |

Filtration | Wash solid residues with solvent; LiBH4 in filtrate is pure (11B-NMR) |

You need to control the temperature during reduction reactions. Most reactions work best between 30° C and 70° C. You should avoid temperatures below 10° C, as the reduction slows down. You must not exceed the boiling point of your solvent. You can use a water bath or oil bath to keep the reaction steady.

You should stir the reaction mixture well. Good mixing helps the reduction proceed evenly. You can use a magnetic stirrer for small-scale reactions. For larger reactions, you may need a mechanical stirrer. You should add lithium borohydride slowly to the reaction vessel. You must watch for any signs of gas evolution or heat. You should keep the reaction under normal pressure or slightly above, up to 100 mbar.

Note: You should always monitor the reaction progress. You can use thin-layer chromatography (TLC) or NMR to check if the reduction is complete.

You need to quench the reaction after the reduction finishes. You should add water or dilute acid slowly to the reaction mixture. You must do this step carefully, as the reaction can release hydrogen gas. You should keep the vessel cool and add the quenching agent dropwise. You must stir the mixture until gas evolution stops.

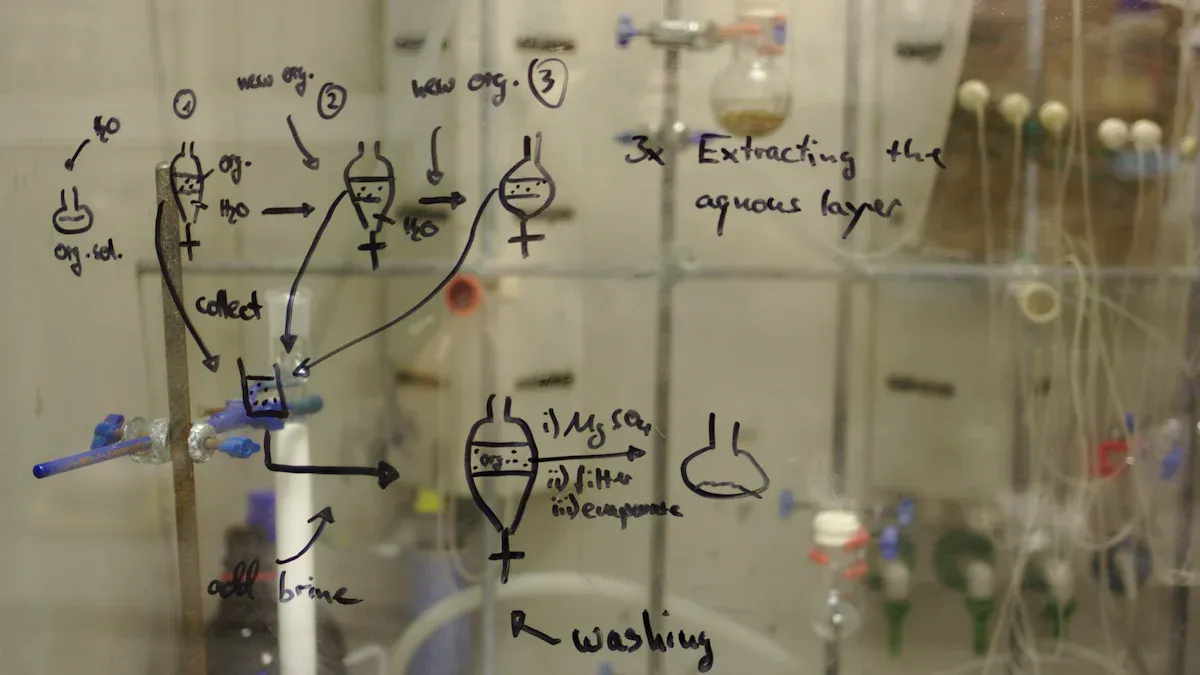

You should separate the product from the reaction mixture. You can use filtration to remove solid residues. You may wash the solids with fresh solvent to recover more product. You can extract the product into an organic solvent, such as ether. You should dry the organic layer over anhydrous magnesium sulfate. You can use rotary evaporation to remove the solvent. You may purify the product further by column chromatography or recrystallization.

Tip: You should verify the purity of your product using NMR or IR spectroscopy. This step ensures your reduction reactions give you the desired results.

You gain several benefits when you choose lithium borohydride for reduction in organic synthesis. This reagent stands out because it can reduce esters to alcohols and primary amides to amines. You find it completely soluble in ethers, which makes it easy to use in many reactions. You also notice that lithium borohydride is safer to handle than lithium aluminum hydride. This safety feature helps you work more confidently in the lab. You can achieve strong reduction without the risks that come with harsher agents.

Tip: You should use lithium borohydride when you want a strong reduction and need to avoid the hazards of lithium aluminum hydride.

You can compare the reduction strength and selectivity of common agents:

Lithium aluminum hydride gives you the strongest reduction. You can reduce esters and carboxylic acids to alcohols.

Sodium borohydride (nabh4) works well for carbonyl reduction but leaves esters unchanged.

Lithium borohydride offers a balance. You get strong reduction and good selectivity for esters, amides, and carboxylic acids.

You must consider some drawbacks when you use lithium borohydride for reduction reactions. The scale of synthesis stays low, usually not exceeding 1 or 2 mmol per batch. This limitation means you use it mainly for laboratory reactions, not for large-scale production. You may struggle to obtain high purity and uniform distribution of the metal. Sometimes you need extra recrystallization steps to improve your product. High energy milling can introduce contamination from the vessel, which affects the quality of your reduction. You may also find that mechanochemical reactions yield amorphous products that need further treatment to crystallize. This process risks decomposition. Incomplete conversion of reagents can leave you with unreacted materials in your product. If you try to synthesize liquid products, the mechanochemical approach may not work well.

Low scale of synthesis restricts you to lab reactions.

Purity and uniformity can be hard to achieve.

Contamination from milling vessels may affect your reduction.

Amorphous products often require extra treatment.

Incomplete conversion can lead to contamination.

Mechanochemical methods may not suit liquid products.

You should select lithium borohydride for reduction when you need to target esters, amides, carboxylic acids, or open epoxides. You get better results than with nabh4, which cannot reduce these functional groups efficiently. You also avoid the extreme reactivity and handling risks of lithium aluminum hydride. If you want a strong reduction and need a reagent that dissolves well in ethers, lithium borohydride gives you a practical solution. You use it for reactions that require selectivity and safety. You should avoid it for large-scale reactions or when you need high purity without extra steps.

Note: You should always match your reducing agent to the functional group and scale of your reaction. Lithium borohydride works best for tough reductions in small-scale lab reactions.

You must always protect yourself when working with lithium borohydride. Wear safety goggles to shield your eyes from splashes during any reduction. Use gloves that resist chemicals, since direct contact can cause burns or irritation. A lab coat keeps your clothes and skin safe from accidental spills. You should also work in a well-ventilated area or use a fume hood. This practice helps you avoid inhaling any fumes that may form during reactions. Remember, even though lithium borohydride is safer than some agents, you still need to treat every reduction with care.

Tip: Always check your PPE before starting a reaction. Replace damaged gloves or goggles right away.

You need to store lithium borohydride in a dry, cool place. Moisture can cause it to react and release hydrogen gas, which creates a fire risk. Keep the container tightly sealed when not in use. Store it away from acids and water to prevent unwanted reactions. You should label the container clearly, so others know about the contents and the risks. If you store nabh4 in the same lab, keep it in a separate area to avoid confusion during reactions.

Storage Requirement | Why It Matters |

|---|---|

Dry, cool location | Prevents unwanted reaction |

Sealed container | Stops moisture from entering |

Clear labeling | Ensures safe handling |

Sometimes, you may notice that your reduction does not go to completion. If you see starting material left after the reaction, check your procedure. You might not have used enough lithium borohydride. Make sure you measure the reagent accurately before starting the reaction. Stirring helps the reduction proceed evenly, so always keep the mixture moving. If the temperature is too low, the reaction may slow down or stop. Try raising the temperature within the safe range for your solvent. You can also compare your results to nabh4 reductions. If nabh4 works better for your substrate, consider switching agents for future reactions.

Note: Always monitor your reactions with TLC or NMR. These tools help you catch incomplete reduction early.

You may sometimes see side reactions during a reduction. These can lower your yield or create unwanted products. If you add lithium borohydride too quickly, the reaction may become too vigorous. This can lead to byproducts or even decomposition. Always add the reagent slowly and control the temperature. Impurities in your solvent or substrate can also trigger side reactions. Use high-purity chemicals for the best results. If you notice side reactions that do not occur with nabh4, review your reaction setup. Sometimes, switching to nabh4 for less reactive substrates can help you avoid these problems.

Add lithium borohydride slowly to control the reaction.

Use pure solvents and substrates to reduce side reactions.

Compare with nabh4 reactions to find the best approach.

Alert: If you see unexpected gas or color changes, stop the reaction and check for side reactions right away.

You often work with lithium borohydride in laboratory settings when you need a strong reducing agent. Many organic chemists choose this reagent for reactions that nabh4 cannot complete. You see lithium borohydride used in the reduction of esters, amides, and carboxylic acids. These reactions help you create alcohols and amines from tough starting materials. You may also use lithium borohydride to open epoxides, which gives you access to new alcohols for further reactions.

One documented example involves achiral and stereospecific reductive boronation at phosphorus. Researchers used lithium borohydride to form alkoxyphosphonium salts in a stereoselective manner. This reaction did not show electronic effects on the stereoselectivity, which means you can expect consistent results. You may find this method useful when you need to control the outcome of your reactions. The article "Lithium Borohydride for Achiral and Stereospecific Reductive Boronation at Phosphorus" in the European Journal of Organic Chemistry describes this process in detail.

You often compare lithium borohydride to nabh4 in your experiments. Nabh4 works well for simple reductions, such as converting aldehydes to alcohols. You use lithium borohydride when nabh4 fails to reduce more resistant functional groups. You notice that reactions with lithium borohydride proceed quickly and give you higher yields for esters and amides. You may run several reactions side by side to see which reagent works best. You learn that nabh4 is safer for basic reductions, but lithium borohydride is essential for challenging reactions.

Tip: You should always monitor your reactions with TLC or NMR to check if the reduction is complete. This practice helps you avoid incomplete reactions and ensures you get the desired product.

You see lithium borohydride used in industry for large-scale organic synthesis. Many companies rely on this reagent for reactions that produce key intermediates in pharmaceuticals. You find that nabh4 is common for simple reductions, but lithium borohydride is preferred when reactions require stronger reduction power. You may work with processes that convert esters, amides, and nitriles to alcohols and amines. These reactions are essential for drug production.

You also see lithium borohydride used in the synthesis of boron-containing drugs. Some companies use it to make BNCT agents for cancer treatment. You notice that these reactions require precise control and high purity. Nabh4 cannot always deliver the needed results, so lithium borohydride becomes the reagent of choice.

Here is a summary of notable industrial applications:

Application Type | Description |

|---|---|

Reducing Agent | Used in the pharmaceutical industry to reduce esters, amides, and nitriles to alcohols and amines, essential intermediates in drug production. |

Synthesis of Drugs | Employed in the synthesis of boron-containing drugs and BNCT agents for cancer treatment. |

You may work with automated systems that handle lithium borohydride safely. You see that reactions in industry often use large reactors and strict controls. You learn that nabh4 is still important for less demanding reactions, but lithium borohydride is vital for advanced synthesis.

Note: You should always follow safety protocols when scaling up reactions. Industrial reactions with lithium borohydride require careful handling and monitoring.

You gain practical benefits when you use lithium borohydride for reduction in organic synthesis. This reagent gives you high selectivity and strong reduction for esters, amides, carboxylic acids, and epoxides. You see efficient reduction, even in challenging cases. The table below highlights its unique features:

Feature | Description |

|---|---|

Selectivity | High for reduction of tough functional groups |

Environmental Impact | Low, with efficient extraction and separation |

Battery Performance | High ionic conductivity and stable reduction properties |

You should always follow safety guidelines to ensure each reduction proceeds smoothly and safely.

You use lithium borohydride for stronger reductions. It reduces esters, amides, and carboxylic acids. Sodium borohydride works best for aldehydes and ketones. Lithium borohydride gives you more options for tough functional groups.

You should not use water or alcohol as solvents. Lithium borohydride reacts with them and loses its reducing power. Choose dry, aprotic solvents like THF or 1,2-dimethoxyethane for safe and effective reactions.

You must wear gloves, goggles, and a lab coat. Keep lithium borohydride dry and away from moisture. Store it in a sealed container. Work in a fume hood for extra safety. Always follow lab safety rules.

You can reduce esters, amides, carboxylic acids, nitriles, and epoxides. You also use it for aldehydes. Lithium borohydride gives you strong reduction for groups that resist sodium borohydride.

You should check your measurements and reaction temperature. Stir the mixture well. Use TLC or NMR to monitor progress. If you see starting material, add more lithium borohydride or adjust conditions.

You add water or dilute acid slowly to the reaction mixture. Stir gently and keep the vessel cool. Watch for hydrogen gas. Quench dropwise until gas stops. Use caution during this step.

You usually use lithium borohydride for small-scale lab reactions. Industrial processes need strict controls and safety measures. For large-scale reductions, you may need other agents or specialized equipment.

You convert esters to alcohols. The reaction gives you high yields and clean products. Lithium borohydride works better than sodium borohydride for this transformation.